1Equipment principle and composition:

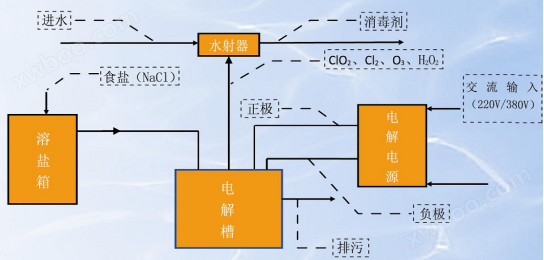

The electrolytic chlorine dioxide generator is a device that electrolyzes saturated sodium chloride (NaCl) aqueous solution in an electrolytic cell with a diaphragm to produce chlorine dioxide as a synergistic disinfectant. The equipment consists of an electrolytic cell, an electrolytic power supply, a dosing device (water injector), and inlet and outlet pipelines.

The electrolytic power supply converts alternating current into direct current with a voltage not exceeding 12V. Electrolyze saturated sodium chloride aqueous solution in a special electrode plate (titanium coated with rare metal oxides of ruthenium, rhodium, iridium, platinum) and UPVC electrolytic membrane electrolytic cell to produce chlorine dioxide synergistic disinfectant. The disinfectant dosing system automatically adds the chlorine dioxide co disinfectant generated by the equipment to the water to be disinfected.

Product schematic diagram

Electrolytic Cell Structure Diagram

IIScope of Equipment Application

IIIequipment installation

1. As the equipment is a live device, it must be installed and used indoors to avoid rain and sun exposure. Indoor temperatureThe temperature range is 0 ℃ to 45 ℃. If it exceeds this range, indoor heating and cooling facilities should be added. The air is relatively humidThe degree should not exceed 85% and the ventilation should be good.

2. The equipment room must have a tap water supply pipe with a pressure of 1.5Mp-4.5Mpa and a diameter of DN15-DN50,Provide water supply to the equipment (the water pressure and pipe diameter vary depending on the size of the equipment model).

3. There must be drainage facilities (floor drains or drainage pipes) in the equipment room.

4. The equipment room is equipped with pipelines (diameter DN15-DN50, not less than the set) connected to the disinfectant dispensing pointPrepare water supply pipes.

5. A low-level exhaust fan with a power of 40W should be installed in the equipment room, with a distance of no more than 0.5 meters from the ground; And fullyThe quantity is close to the equipment.

6. Two PVC-U ventilation pipes with diameters of DN15-DN32 for water supply should be installed in the equipment room, close to the equipmentThe height above the ground shall not be less than 2 meters.

7. There is no direct sunlight, no severe vibration, good ventilation, no flammable or explosive dust, and no corrosion in the equipment roomGases that corrode metals and damage insulation.

8. The distance between the equipment and the four walls shall not be less than 0.5 meters.

9. The equipment uses a voltage of 220 volts or 380 volts; When the equipment model is less than 300, use voltageWhen the equipment model is greater than 300 (including 300), the voltage used is 380 volts, which is 220 volts. UseIf the voltage of the power supply exceeds 10%, please prepare a voltage regulator in advance.

10. The equipment uses industrial refined salt or edible refined salt, and the sodium chloride content is not less than 95%.

11. The net area between devices should reach 6-25 square meters (installation area varies depending on the size of the device model)Different).

12. Our company's installation project is limited to indoor installation construction. Please install outdoor trench and pipe laying projects in advanceArrange for preparation; The diameter of the outdoor disinfectant dosing pipeline should be equal to the diameter of the indoor water supply pipe.

13. If the distance between equipment is more than 20 meters from the water well or clean water tank, or if the ground level between equipment is lower than that of the clean water tankWhen adding ports, please bring your own pipeline pump with a lift of not less than 30 meters.

4characteristic

1. Using salt as the raw material; Salt consumption: ≤ 1.6 grams of salt per gram of available chlorine.

2. The device can automatically adjust the amount of disinfectant produced based on the measurement signal of the residual chlorine measuring instrument or the flow signal of the flow meter.

3. The production of effective chlorine can be monitored online, and equipment parameters can be monitored online, making it easy for higher-level departments to supervise and manage. Equipped with an automatic control micro PLC, it can achieve continuous and precise control of the production of chlorine dioxide composite disinfectant from zero to maximum (control accuracy: 1 gram of effective chlorine/hour), and can also achieve remote monitoring and control; Simultaneously package and send the operating parameters of other devices to the supervisory and management center of the higher-level unit to achieve effective administrative management.

4. The equipment adopts an automatic salt dissolution system, which does not require manual preparation of saturated saline solution. When the equipment is short of salt, only solid salt is added,.

5. The equipment automatically controls the temperature of the electrolytic cell to not exceed 40 degrees Celsius.

6. The electrolytic diaphragm has low resistivity, corrosion resistance, no need for cleaning, and long service life.

7. The electrolytic electrode plate is made of titanium mesh coated with ruthenium, rhodium, iridium, and platinum.

8. The equipment automatically replenishes water and discharges pollutants.

9. The electrolytic power supply adopts intelligent high-frequency switching power supply, and the main components of IGBT module, rectifier module, and rectifier bridge are all imported accessories; The electrolytic power supply can operate continuously at full load for a long time.